[/caption]

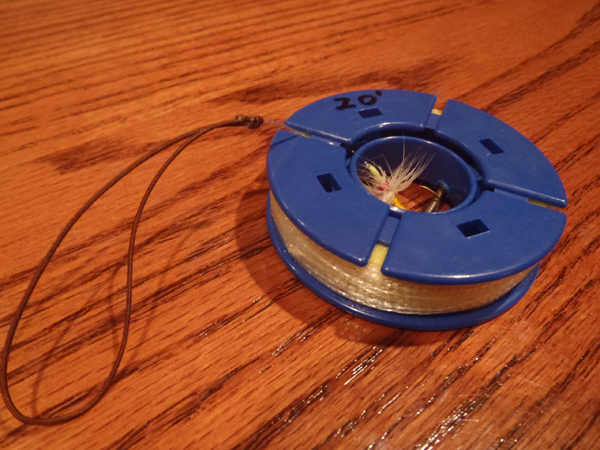

Today, I got my long awaited Nissin Prosquare tenkara rod in the mail (review coming soon). A friend in Japan who bought and sent the rod to me was kind enough to also include a 20 ft. furled line he made himself and one of his flies. Thanks Eiji! The line looks a lot like the horse hair tenkara lines I recently made, with different snoods knotted together. After reading Daniel’s article on long line tenkara, I am really excited to try it out. I was a little surprised to see that he sent it on the same Meiho mini line spool Tenkara Bum sells. But upon closer inspection, I noticed an even better surprise.

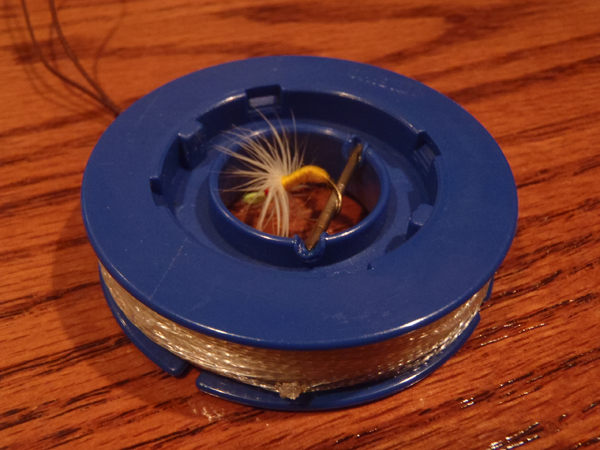

He made a very interesting modification to the spool that really grabbed my attention. Basically, it looks like he added a metal rod to the inside hole of the spool by heating it and melting it into the plastic to secure it. This is to hold the fly. I can immediately see the advantage of this. The fly is protected from being crushed by being inside the hole. I’ve had plenty of flies get pretty matted down in storage when I stored them on the outside of the spool so I thought this was a really clever idea.

And in case you’re wondering, he offset the metal rod so there is still enough space to thread your rod though. I think this is a great DIY mod and it looks pretty easy to do. I’m imagining you simply grab the metal rod with pliers, heat it up with a lighter, push it down into the plastic and when it cools, it’s secure. Just wanted to pass it along in case anyone wants to try it.

20 foot furled line!! Can’t wait to read your review. Cool mod on the line spool.

You will have to tell us all how the line casts and does the line coil up if pulled from a snag.

Looking forward to the review.

Tj

TJ, I think it will coil because I believe it’s mono but I won’t be able to say for sure until I get it out on the water.

My main concern about a furled long line is not coiling from snag but a tangle on the rod tip. When cast, the loop of the taper line is twisted and can tangle on the rod tip. In order to diminish this issue, I use lillian for the line loop.

I have never broken my rod tip due to such tangle, but pay attention often to your rod tip before you cast.

Thanks for the tip Eddie! Unfortunately, lilian is difficult to find in the U.S.

Lillian?

What color would you like?

Oh, and what diameter?

I have three colors and three diameters in stock.

I never got around to putting it on the website because it’s something that most anglers will ever need.

Like the idea for spool Jason. Can’t wait to hear about the rod!

Chris, could you email me the prices and colors at loftend@gmail.com thanks

Loften,

Just curious, are you going to use lilian for leaders like Eddie did or are you saving it to replace on rods if they get worn out?

I am going to try messing around with some flies with it. I’m always looking for new materials. I may also make a leader or two with it.

I have not modified any of my blue spools. But they snap apart very easily by pushing on 4 clips using a small screwdriver so you can modify the spool more cleanly as shown in the web page linked below.

Here is a link to the Japanese web site showing how he modified the blue spool in two different ways using a paper. No melting of the spool. Just drill a couple of holes using a pen drill.I like the one with using the curved end of the paper clip the best. He also makes one with a straight bar across similar to the your spool was done. I think the offset to the side the way your spool shows it is better since it leaves the center hole more open. All you need is a larger paper clip, a small drill bit, some wire cutters and some glue. The pictures on the Japanese web site are self explanatory.

http://mrbigfactory.hama1.jp/e93076.html

That is a GREAT easy suggestion about inserting that metal bar! I always hate my flies getting squished in storage in my backpack. I think I’ll try this out with a thick paperclip and a lighter.

Hi Jason I have taken the idea of the stem but making any changes I drilled two small 1.2mm hole and I made it past the pin into the holes and all the consolidated some cyanoacrylate glue

Nice work Robert!

Looks good Robert! What did you use for the bar. A nail?

Hi Jason,

Welding rod for brazing titanium work remains flexible enough to twist it a bit to go in the holes